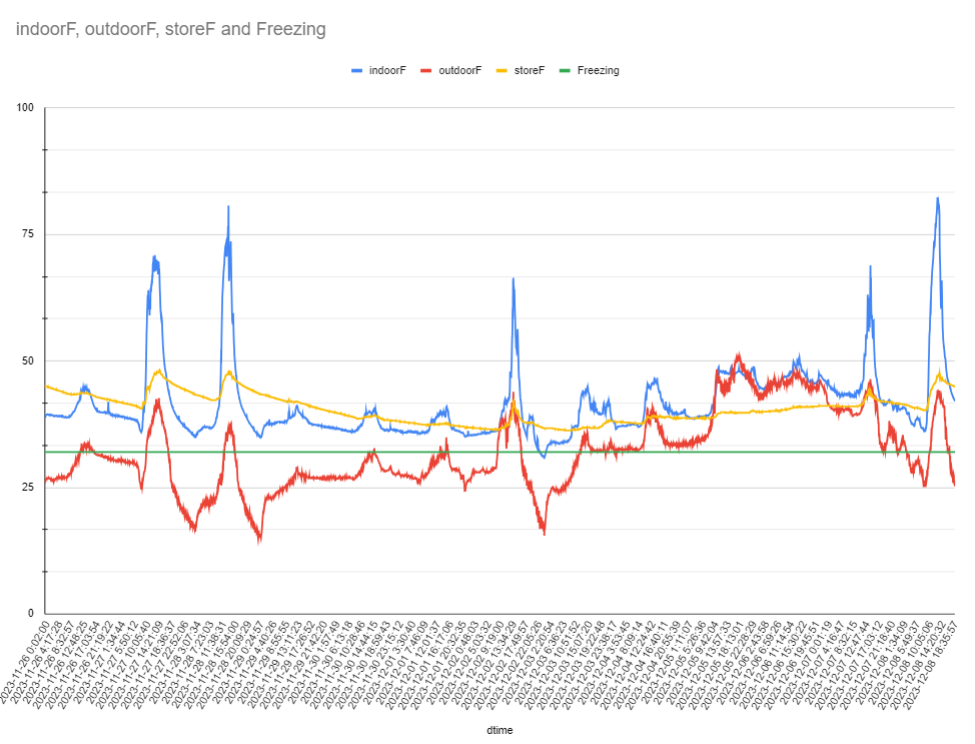

4 season Greenhouse Update during freezing winter conditions temperature log update Nov-26 to Dec-8

Our off-grid, 4-season greenhouse recently navigated a challenging period marked by heavy cloud cover, freezing nights with temperatures dipping under 16F. This period provided valuable insights into the system’s performance under extreme conditions and highlighted areas for potential enhancements.

Observations During the Cold Spell

On December 3rd, with outdoor temperatures reaching a low of 15.6°F, our indoor temperature briefly fell under freezing to 30.92°F. The thermal storage barrels, at 36.8°F, played a key role in moderating the temperature drop. The spinach tolerated these conditions with no visible affect. The willow plants exhibited some stress including loosing some leaves. This scenario illustrated the need for faster heat delivery during extreme temperature drops. It also shows the need to reduce thermal loss so the existing thermal storage can keep up. Reducing thermal losses would also have ensured the thermal storage started at a higher peak temperature which would have allowed it to deliver more BTU during the critical period.

Current State of the Greenhouse

As of December 8th, the greenhouse continues to support plant growth through freezing nights. This period has been an important test of the existing setup’s resilience and the effectiveness of implemented strategies.

I love conditions that test the limits of our prior engineering so we can see what needs to be improved.

Joseph Ellsworth Dec-8-2024

Planned Improvements and Strategies

In response to these observations, several enhancements are being considered:

- Enhanced Insulation with Additional Glazing: Initial results from installing inner glazing layers indicate a promising reduction in heat loss, potentially over 55%.

- Light and Insulation Optimization: Combining affordable polycarbonate with insulating panes (Duck brand Window film showing over R5 and vinyl over R3.5) aims to strike a balance between insulation efficiency and light transmission.

- Geo-Exchange System Integration: The installation of a Geo-Exchange system is underway to supplement the thermal storage barrels, particularly beneficial during extended periods of cloud cover and freezing temperatures.

- Automated Temperature Regulation: We are exploring the use of an automated fan system to maintain above-freezing temperatures inside the greenhouse by activating a fan whenever to blow air past the thermal barrel whenever air temperatures drop close to freezing.

Continued Learning and Adaptation

These experiences in extreme weather conditions have been instrumental in understanding the strengths and limitations of our greenhouse setup. Each observation guides us in fine-tuning our approach and informs our future decisions.

Collaborative Opportunity

We are considering making our custom-designed data logger PCBs available for others interested in detailed environmental monitoring, estimated at around $150 each.

Ways to prevent frost damage under similar conditions:

- Improve insulation value from the glazing to allow the heat exchange with thermal barrels to deliver heat fast enough to keep the air above freezing.

- Increase surface area of the thermal storage barrels to exchange more heat

- Increase the water temperature in the barrels so they can deliver more heat.

- Increase thermal exchange with the barrels using a blower when air indoor is approaching freezing so they can deliver enough heat to keep the air above freezing.

One response to “4 season Greenhouse in Freezing Conditions: Insights and Future Enhancements”

[…] 4 season Greenhouse in Freezing Conditions: Insights and Future Enhancements […]